CCTV News:This year is the closing year of the blue sky defense war. Last year, the Ministry of Ecology and Environment and other five ministries and commissions jointly issued the Opinions on Promoting the Implementation of Ultra-low Emission in the Steel Industry, clearly stating that by the end of 2020, the ultra-low emission transformation of steel enterprises in key areas should make significant progress. Then, it is less than two months before the end of the year. At present, what is the progress of ultra-low emission transformation in iron and steel enterprises?

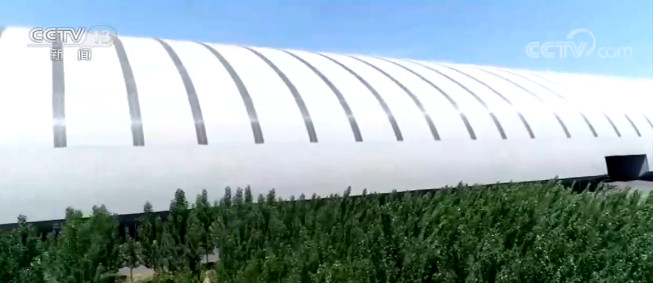

To produce one ton of steel, 3.5 tons of various raw materials are needed. For iron and steel enterprises, how to reduce the emission pollution caused by raw materials in the process of transshipment and storage is actually the first process of ultra-low emission transformation. In Handan Xinjin Iron and Steel Company, the reporter saw five greenhouses with a total area of 260,000 square meters, which "covered" all the main links that caused pollution.

It is as small as adjusting the water mist diameter of the spraying device and sprinkling water regularly in the factory, and as large as transporting the fully sealed iron inside the factory and transporting the revolving iron outside the factory. Through a series of transformation, Xinjin Iron and Steel can reduce particulate emissions by 3,200 tons per year.

The second key to ultra-low emission is the smelting process. In Qian ‘an, Tangshan, shougang shares Qian ‘an Iron and Steel Company has just completed the 20th upgrading of sintering and pelletizing desulfurization and denitrification devices. The real-time emission index of sintering machine has been reduced to a very low level by increasing the denitration process of independent innovation.

According to the data provided by China Iron and Steel Industry Association, at present, there are 229 steel enterprises in China with 620 million tons of crude steel capacity undergoing ultra-low emission transformation.

关于作者